Exploring ERP Systems for Manufacturing: Enhancing Efficiency and Innovation

TABLE OF CONTENTS

- Introduction

- Importance of ERP Systems in Manufacturing

- Key Features of ERP Systems for Manufacturing

- Factors to Consider When Choosing an ERP System

- Top ERP Systems for Manufacturing

- Cost Considerations

- Customization Options

- Integration Capabilities

- Cloud-Based vs. On-Premise ERP Systems

- Implementation Process

- Challenges in Implementing ERP Systems

- Success Stories in Manufacturing

- Future Trends in ERP for Manufacturing

- Conclusion

- FAQs about ERP Systems for Manufacturing

Introduction

In today’s competitive manufacturing landscape, ERP systems play a crucial role in integrating various business processes into a unified platform. This article explores how ERP systems can transform manufacturing operations, improve efficiency, and drive growth.

Importance of ERP Systems in Manufacturing

ERP systems are essential for manufacturing companies to achieve operational excellence. By centralizing data and automating workflows, ERP systems enhance production efficiency, reduce costs, and ensure better decision-making across all levels of the organization.

Key Features of ERP Systems for Manufacturing

Modern ERP systems for manufacturing offer a range of features tailored to industry-specific needs:

Manufacturing Resource Planning (MRP)

MRP capabilities allow manufacturers to plan production schedules, manage inventory levels, and optimize resource utilization.

Production Scheduling Software

Advanced production scheduling software helps manufacturers sequence tasks, allocate resources, and minimize downtime.

Inventory Management Systems

Effective inventory management systems track raw materials, work-in-progress, and finished goods to maintain optimal stock levels.

Shop Floor Control

Real-time shop floor control tools monitor production activities, track work orders, and ensure adherence to production schedules.

Supply Chain Optimization

ERP systems optimize supply chain operations by improving procurement processes, enhancing supplier relationships, and reducing lead times.

Factors to Consider When Choosing an ERP System

Selecting the right ERP system requires careful consideration of several factors:

Industry-Specific Needs

Choose an ERP system that aligns with the unique requirements of the manufacturing industry, such as regulatory compliance and production complexity.

Scalability

Ensure the ERP system can scale with your business growth and accommodate increasing production volumes without performance issues.

Integration Capabilities

Evaluate the ERP system’s ability to integrate seamlessly with existing software applications, such as CRM and financial management systems.

User-Friendly Interface

An intuitive user interface facilitates adoption and reduces training time for employees across different departments.

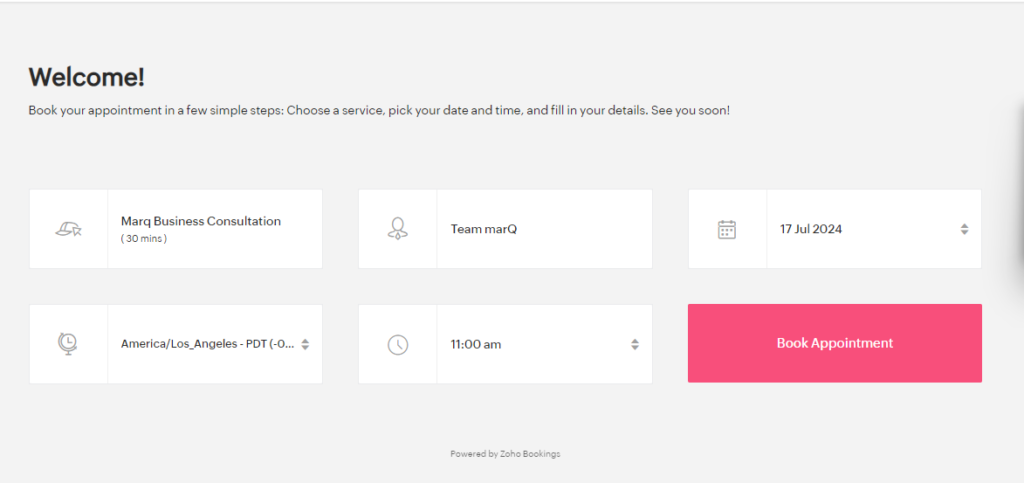

CLAIM YOUR MARKETING STRATEGY SESSION TODAY!

WE REVIEW YOUR MARKETING EFFORTS & SHOW YOU AREAS TO IMPROVE.

Top ERP Systems for Manufacturing

Explore some of the leading ERP systems recommended for manufacturing businesses:

SAP S/4HANA

Known for its robust MRP capabilities and real-time analytics, SAP S/4HANA helps manufacturers optimize production processes and enhance supply chain visibility.

Oracle Manufacturing Cloud

Oracle Manufacturing Cloud offers comprehensive manufacturing management functionalities, including production planning, quality management, and shop floor execution.

Microsoft Dynamics 365 for Finance and Operations

Microsoft Dynamics 365 integrates production planning, inventory management, and supply chain logistics to improve manufacturing efficiency and responsiveness.

Epicor ERP

Epicor ERP provides industry-specific solutions for manufacturers, focusing on scalability, flexibility, and operational efficiency.

Infor CloudSuite Industrial (SyteLine)

Infor CloudSuite Industrial (SyteLine) offers specialized tools for discrete and process manufacturers, enabling streamlined operations and enhanced customer service.

Cost Considerations

Managing costs is crucial for manufacturing businesses. Consider these cost-related factors when selecting an ERP system:

Total Cost of Ownership (TCO)

Evaluate upfront costs, ongoing maintenance fees, and potential customization expenses to determine the TCO of the ERP system.

Return on Investment (ROI)

Calculate the potential ROI by assessing how the ERP system can improve operational efficiency, reduce waste, and increase production output.

Subscription vs. License Fees

Compare subscription-based ERP solutions with one-time license fees to find the most cost-effective option for your budget.

Customization Options

Tailoring the ERP system to meet specific manufacturing requirements can enhance its effectiveness:

Customizable Workflows

Adapt ERP workflows to align with unique production processes, quality control standards, and regulatory requirements.

Industry-Specific Modules

Choose ERP systems that offer industry-specific modules for manufacturing, such as lean manufacturing practices or batch process management.

Mobile Accessibility

Enable mobile access to ERP functionalities for shop floor employees, enabling real-time data entry and production status updates.

Integration Capabilities

Integration with other business systems is essential for seamless data flow and operational efficiency:

CRM Integration

Integrate ERP with CRM systems to enhance customer relationship management and sales order processing.

Financial System Integration

Link ERP with financial management software for accurate accounting, financial reporting, and cost analysis.

Supply Chain Integration

Optimize supply chain management by integrating ERP with logistics and procurement systems to improve inventory control and supplier collaboration.

Cloud-Based vs. On-Premise ERP Systems

Choose between cloud-based and on-premise ERP deployment models based on your business needs and preferences:

Cloud-Based ERP Systems

Cloud-based ERP systems offer flexibility, scalability, and accessibility from anywhere with internet connectivity, making them ideal for remote teams and global operations.

On-Premise ERP Systems

On-premise ERP solutions provide greater control over data security and customization but require upfront investments in hardware infrastructure and IT resources.

Implementation Process

Successful ERP implementation involves several key stages:

Planning and Preparation

Define project goals, establish a project team, and conduct a thorough needs assessment to align ERP functionalities with business requirements.

Data Migration and Integration

Transfer existing data into the new ERP system while ensuring data integrity, accuracy, and compatibility with legacy systems.

Training and Change Management

Provide comprehensive training sessions for employees to familiarize them with ERP functionalities and ensure smooth adoption across the organization.

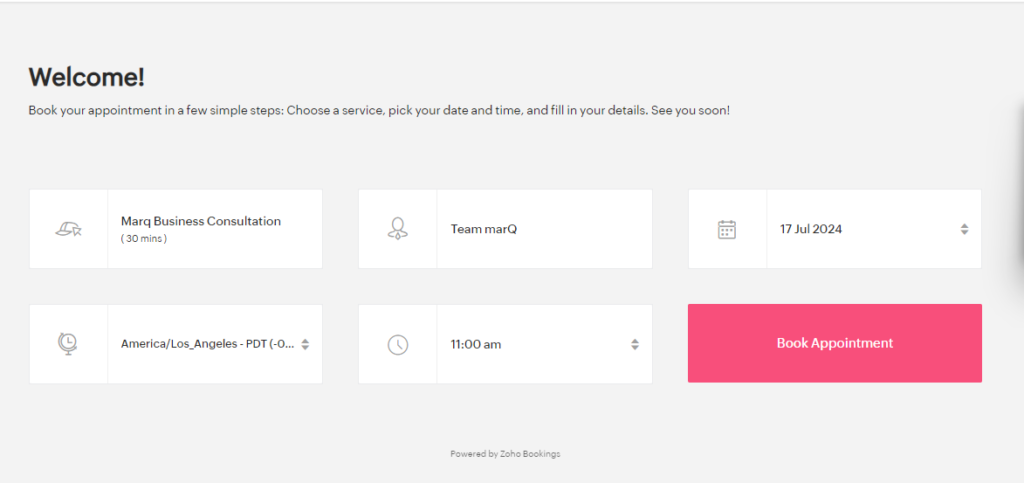

CLAIM YOUR MARKETING STRATEGY SESSION TODAY!

WE REVIEW YOUR MARKETING EFFORTS & SHOW YOU AREAS TO IMPROVE.

Challenges in Implementing ERP Systems

Overcoming challenges during ERP implementation is crucial for achieving successful outcomes:

Resistance to Change

Address employee resistance through effective communication, training programs, and highlighting the benefits of ERP adoption.

Data Migration Issues

Ensure data accuracy and completeness during the migration process to prevent disruptions in daily operations and reporting.

Budget Constraints

Manage ERP implementation costs by prioritizing essential functionalities, negotiating with vendors, and planning for contingencies.

Success Stories in Manufacturing

Learn from manufacturing businesses that have achieved significant improvements with ERP systems:

Case Study: XYZ Automotive

XYZ Automotive enhanced production efficiency by 30% after implementing SAP S/4HANA for streamlined production planning and supply chain management.

Case Study: ABC Electronics

ABC Electronics improved inventory accuracy and reduced lead times by 50% with Oracle Manufacturing Cloud’s advanced inventory management features.

Case Study: LMN Pharmaceuticals

LMN Pharmaceuticals optimized batch processing and compliance with industry regulations using Epicor ERP’s specialized pharmaceutical manufacturing modules.

Future Trends in ERP for Manufacturing

Stay ahead of industry trends with these emerging developments in ERP technology:

Internet of Things (IoT) Integration

Utilize IoT devices for real-time data collection, predictive maintenance, and enhanced operational visibility within manufacturing processes.

Artificial Intelligence (AI) and Machine Learning

Implement AI-driven analytics to optimize production forecasting, quality control, and supply chain logistics for improved decision-making.

Blockchain for Supply Chain Transparency

Enhance supply chain traceability and transparency by leveraging blockchain technology for secure transaction recording and product provenance.

Conclusion

ERP systems have revolutionized manufacturing operations by integrating critical business processes, enhancing efficiency, and enabling data-driven decision-making. Choosing the right ERP system tailored to your manufacturing needs is essential for achieving sustainable growth and competitive advantage in the industry.

FAQs

MRP in ERP systems helps manufacturers plan production schedules, manage inventory, and optimize resource allocation to meet production demands effectively.

ERP systems improve supply chain management by optimizing procurement processes, enhancing supplier relationships, and reducing lead times for raw materials and finished goods.

Challenges in ERP implementation include data migration issues, resistance to change among employees, and managing upfront costs while ensuring ROI.

Customization allows manufacturing businesses to tailor ERP functionalities to meet specific production processes, quality standards, and regulatory requirements.

Cloud-based ERP systems offer scalability, flexibility, and accessibility from anywhere, supporting remote operations, global supply chains, and real-time data insights.

This article provides a comprehensive overview of ERP systems for manufacturing, addressing key features, considerations, top solutions, implementation strategies, challenges, success stories, future trends, and FAQs. For more information on choosing the best ERP system for your manufacturing business, visit MARQ Networks.

ABOUT THE AUTHOR:

Syeda Hufsa

Syeda Hufsa is the Content Creation Specialist at marQ Networks. Syeda Hufsa loves writing both personally and professionally. She graduated from reupdated university field of Computer science.